April 6, 2021

Each person’s body is unique — 3D printing really shines in healthcare applications by enabling customized solutions. Whether it is a cast printed from a 3D scan of a child’s forearm, new tissue to repair an injury or entirely new organs manufactured with embedded vascular structure, researchers are creating new applications for 3D printing in healthcare at a lightning pace.

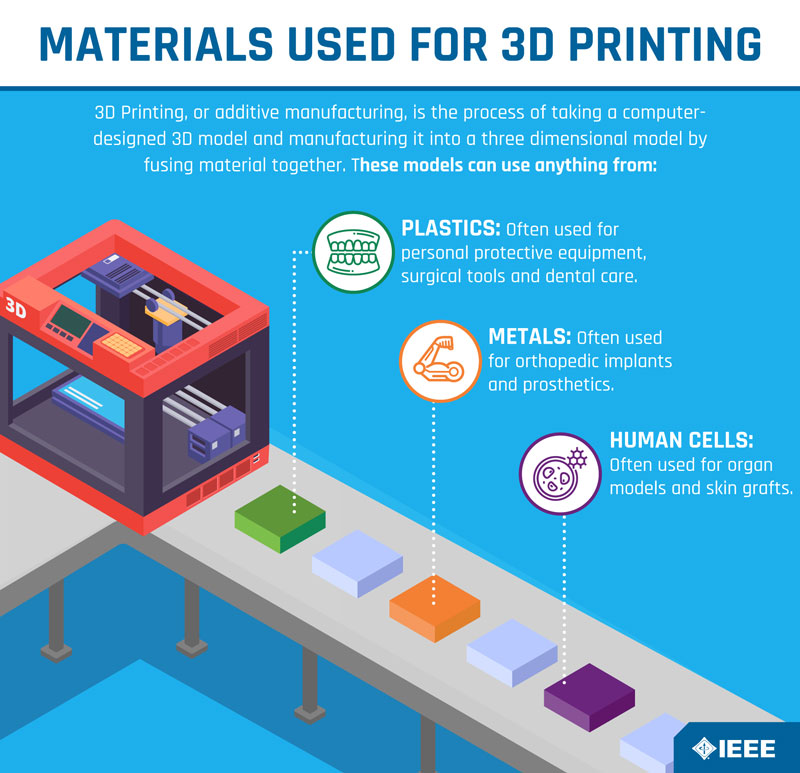

3D Printing, or additive manufacturing, is the process of taking a computer-designed 3D model and manufacturing it into a three dimensional model by fusing material together. There are many different types of 3D printing, which use a variety of base materials: plastics, metals, even human cells. By building up the material, typically in layers, you can produce highly complex shapes and designs not possible in traditional manufacturing.

Because of the ability to individualize 3D printing in healthcare, surgeons can perform practice sessions on duplicate copies of patient’s organs to improve success rates. On the

nanoscale, doctors can perform more precisely targeted drug delivery.

See also Additive Manufacturing is Filling in the Gaps for Medical Face Shield Demand

How Healthcare is Using 3D Printing Globally

3D printing in healthcare is a growing subsector. Some uses have reached global application, but many are still in the research phase. 3D printing of prosthetics, for example, has enabled more affordable custom prosthetic manufacturing in lower-income communities around the world.

The COVID-19 pandemic has reemphasized the need for open-source medical supply designs that can be shared globally and 3D printed locally. Engineers have made personal protective equipment, ventilator supplies and manual tools to help our healthcare providers stay safe and effective as they fight the spread of the disease.

How Additive Manufacturing is Helping in the Fight Against COVID-19

The Future of 3D Printing in Healthcare

Some of the research I mentioned above can transform the way we treat organ failure. I’m intrigued by the idea of using a person’s own cells to 3D print new organs to reduce rejection rates like those seen in organ transplants.

See also 3D Organs and Bones Will Make Transplant Lists a Thing of the Past

As a new technology, improving consistency and reliability in 3D printing is hugely important as it moves into life-sustaining applications. We call a misplaced blob of plastic a print failure, but that wouldn’t be acceptable on the cellular level. Ideally, to improve the consistency and in-situ quality control of the 3D printing processes, especially for custom applications would enable greater expansion into medical fields.

ABOUT OUR AUTHOR

IEEE Impact Creator Samantha Snabes is committed to significantly reducing the cost and scale barriers for industrial 3D printing. Snabes co-founded Texas-based startup re:3D in 2013 which later pioneered the world’s first affordable, human-scale, industrial filament-based 3D printer. As a serial entrepreneur, Snabes previously served as the Social Entrepreneur in Residence for the NASA HQ and Deputy Strategist supporting the NASA Johnson Space Center’s Space Life Sciences Directorate.

Re:3D ambassador Charlotte Craff also contributed to the article.

Liquid Infrastructure: Our Planet's Most Precious Resource

Liquid Infrastructure: Our Planet's Most Precious Resource The Impact of Technology in 2025

The Impact of Technology in 2025 Quantum and AI: Safeguards or Threats to Cybersecurity?

Quantum and AI: Safeguards or Threats to Cybersecurity? Why AI Can't Live Without Us

Why AI Can't Live Without Us Bits, Bytes, Buildings and Bridges: Digital-Driven Infrastructure

Bits, Bytes, Buildings and Bridges: Digital-Driven Infrastructure Impact of Technology in 2024

Impact of Technology in 2024 Emerging AI Cybersecurity Challenges and Solutions

Emerging AI Cybersecurity Challenges and Solutions The Skies are Unlimited

The Skies are Unlimited Smart Cities 2030: How Tech is Reshaping Urbanscapes

Smart Cities 2030: How Tech is Reshaping Urbanscapes Impact of Technology 2023

Impact of Technology 2023 Cybersecurity for Life-Changing Innovations

Cybersecurity for Life-Changing Innovations Smarter Wearables Healthier Life

Smarter Wearables Healthier Life Infrastructure In Motion

Infrastructure In Motion The Impact of Tech in 2022 and Beyond

The Impact of Tech in 2022 and Beyond Cybersecurity, Technology and Protecting Our World

Cybersecurity, Technology and Protecting Our World How Technology Helps us Understand Our Health and Wellness

How Technology Helps us Understand Our Health and Wellness The Resilience of Humanity

The Resilience of Humanity Harnessing and Sustaining our Natural Resources

Harnessing and Sustaining our Natural Resources Creating Healthy Spaces Through Technology

Creating Healthy Spaces Through Technology Exceptional Infrastructure Challenges, Technology and Humanity

Exceptional Infrastructure Challenges, Technology and Humanity The Global Impact of IEEE's 802 Standards

The Global Impact of IEEE's 802 Standards Scenes of our Cyber Lives: The Security Threats and Technology Solutions Protecting Us

Scenes of our Cyber Lives: The Security Threats and Technology Solutions Protecting Us How Millennial Parents are Embracing Health and Wellness Technologies for Their Generation Alpha Kids

How Millennial Parents are Embracing Health and Wellness Technologies for Their Generation Alpha Kids Space Exploration, Technology and Our Lives

Space Exploration, Technology and Our Lives Global Innovation and the Environment

Global Innovation and the Environment How Technology, Privacy and Security are Changing Each Other (And Us)

How Technology, Privacy and Security are Changing Each Other (And Us) Find us in booth 31506, LVCC South Hall 3 and experience the Technology Moon Walk

Find us in booth 31506, LVCC South Hall 3 and experience the Technology Moon Walk Virtual and Mixed Reality

Virtual and Mixed Reality How Robots are Improving our Health

How Robots are Improving our Health IEEE Experts and the Robots They are Teaching

IEEE Experts and the Robots They are Teaching See how millennial parents around the world see AI impacting the lives of their tech-infused offspring

See how millennial parents around the world see AI impacting the lives of their tech-infused offspring Take the journey from farm to table and learn how IoT will help us reach the rising demand for food production

Take the journey from farm to table and learn how IoT will help us reach the rising demand for food production Watch technical experts discuss the latest cyber threats

Watch technical experts discuss the latest cyber threats Explore how researchers, teachers, explorers, healthcare and medical professionals use immersive technologies

Explore how researchers, teachers, explorers, healthcare and medical professionals use immersive technologies Follow the timeline to see how Generation AI will be impacted by technology

Follow the timeline to see how Generation AI will be impacted by technology Learn how your IoT data can be used by experiencing a day in a connected life

Learn how your IoT data can be used by experiencing a day in a connected life Listen to technical experts discuss the biggest security threats today

Listen to technical experts discuss the biggest security threats today See how tech has influenced and evolved with the Games

See how tech has influenced and evolved with the Games Enter our virtual home to explore the IoT (Internet of Things) technologies

Enter our virtual home to explore the IoT (Internet of Things) technologies Explore an interactive map showcasing exciting innovations in robotics

Explore an interactive map showcasing exciting innovations in robotics Interactively explore A.I. in recent Hollywood movies

Interactively explore A.I. in recent Hollywood movies Get immersed in technologies that will improve patients' lives

Get immersed in technologies that will improve patients' lives